FreeMove® Collaborative Palletizing Case Study

By Alberto Moel, VP of Strategy & Partnerships

Welcome back, dear reader, to our first case study of 2021. We are very bullish on 2021, in particular as we are getting ready to launch our ISO 13849 certified FreeMove® system later this quarter. We hope you enjoyed reading our recent in-depth looks at practical collaborative robotics using Speed and Separation Monitoring. The idea behind that series was for you, our esteemed reader, to get a sense for how collaborative robotics can be implemented under the existing ISO 10218 and ISO/TS 15066 standards.

Switching gears a bit, in today’s post we will be looking at a practical case study using FreeMove. As you may recall, we have previously presented examples of FreeMove for in-line assembly, machine tending, and palletizing. In the palletizer case study, we also reviewed how FreeMove can improve the economics of fault recovery and workcell reconfiguration.

In our palletizer implementation (for a large, global Consumer Packaged Goods company) we found that FreeMove was superior in performance and economics to both a fully manual and a fully automated palletizer. That is great, but some customers told us that they have a fine collaborative Power and Force Limited (PFL) robot that works well, is not too expensive, is easy to install and commission, and a cinch to program.

They tell us they want to use it for a simple and safe collaborative palletizer application, like the one in Figure 1, to help improve their processes with some safe human-robot interaction added in. However, when they seek to actually use a PFL robot in palletizing operations, they run into limitations:

The robot can palletize at low rates, but if production rates increase, the maximum speed of the PFL robot becomes a limiting factor.

The limited payload of a PFL robot becomes a constraint on case weights, and the limited reach of a PFL robot means that pallet sizes are limited.

Clamp-style end effectors can’t be used because of potential pinch points.

A risk assessment shows that other hazards in the cell, such as conveyors, require guarding so that the cell must be fenced and is no longer collaborative.

FreeMove eliminates these issues because it allows the use of standard industrial robots, the safeguarding of static hazards, and the automatic stopping of the robot, as well as putting end effectors in a safe state when a human approaches. However, FreeMove’s approach – 3D safeguarding and dynamic speed and separation monitoring – does mean that the robot will be slowed down or stopped when a human production worker is close to it, unlike the ideal case of a PFL robot with small, safe payloads, no end effector or other hazards in the cell, and small pallets.

That raises the question of cycle performance in this ideal case for a PFL robot: If a production worker must enter and leave the workcell regularly to exchange pallets, how does FreeMove’s performance in a palletizing workcell compare against that of a PFL robot?

Figure 1. A simple and safe PFL robot collaborative palletizer.

So, here at Veo, we rose to the challenge, and went ahead and built the palletizer in Figure 1, plus another one incorporating the same PFL robot with a 2D laser scanner (allowing the PFL robot to safely run at full speed, Figure 2), and compared it to a palletizer using a standard workhorse ABB IRB 2600 industrial robot integrated with Veo FreeMove (Figure 3). Again, these are the ideal cases for a PFL robot: No hazards other than the robot, light payloads so that the PFL robot can pick multiple cases at a time, and small pallets.

Figure 2. A simple collaborative palletizer with 2D safety laser scanner.

Figure 3. An ABB IRB 2600 robot palletizer with Veo FreeMove.

If you want to stop reading now, we can happily report that the palletizer with Veo FreeMove is (to use the technical term) a no-brainer compared to the other two options. If you want to know the details of how much of a no-brainer, please read on!

Palletizer Design and Operating Statistics

To test the different palletizer configurations, we built a simple two-pallet palletizer, stacking 48 small boxes in a 4x4x3 configuration. Operation begins with two empty pallets, where the robot begins stacking boxes four at a time on one of the pallets. Once this pallet is full, a human with a pallet jack enters the workcell to withdraw the complete pallet and put in a new empty one as the robot begins filling the empty pallet on the other side.

We tested three configurations:

A simple PFL robot collaborative palletizer (the “PFL Palletizer”, Figure 1). Because the robot and application are inherently safe, the human changing pallets can easily enter and exit while the robot is still moving. However, because it is a PFL robot, it can only move relatively slowly.

To allow for higher throughput, we built a second palletizer using the same PFL robot, but this time installed a 2D safety scanner and used it to trigger a speed limit on the PFL robot. That way, the robot can run at full speed, but if a human were to closely approach, it would slow down to a safe speed (the “PFL + Area Scanner Palletizer”, Figure 2). During normal operation, the human does not come inside the scanner safeguarded area or the 2D scanner triggered.

The third configuration is using a standard ABB IRB 2600 robot safeguarded with a Veo FreeMove system (“ABB + FreeMove Palletizer”, Figure 3). In normal operation, the human enters the safeguarded area, and the robot is temporarily stopped while pallets are exchanged.

We ran the three palletizer configurations and obtained the summary performance statistics in Figure 4.

Figure 4. Summary palletizer operating statistics.

The ABB + FreeMove palletizer has almost five times the throughput of the simple PFL palletizer. With the 2D scanner, allowing the PFL robot to run at full speed, the ABB + FreeMove palletizer is still over twice as fast. Even unconstrained, the PFL robot has speed limitations.[1]

Capital Expenditures and Commissioning Costs

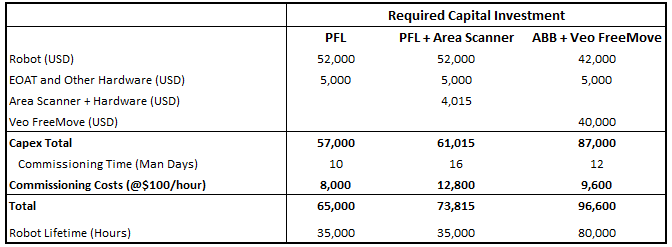

You may rightly ask: that performance comes at a cost, right? Indeed, the PFL + Area Scanner and the ABB + FreeMove palletizers have additional bits and pieces that cost money. And designing and implementing these safety features is not free. We have summarized these in Figure 5.

The ABB + FreeMove palletizer is the most expensive in total. However, FreeMove is designed for ease of installation and hence, the commissioning costs (including workcell electrical and mechanical design, application engineering, and build and install) are only slightly higher than those of the simple PFL robot. Also, the ABB IRB 2600 robot is not only less expensive than the PFL robot[2], but also rated for 80,000 hours, more than twice that of the PFL robot. This will have implications on the per-pallet running costs, as we present below.

Figure 5. Capital expenditures and commissioning costs for palletizing solutions.

Palletizer Running Costs Comparison

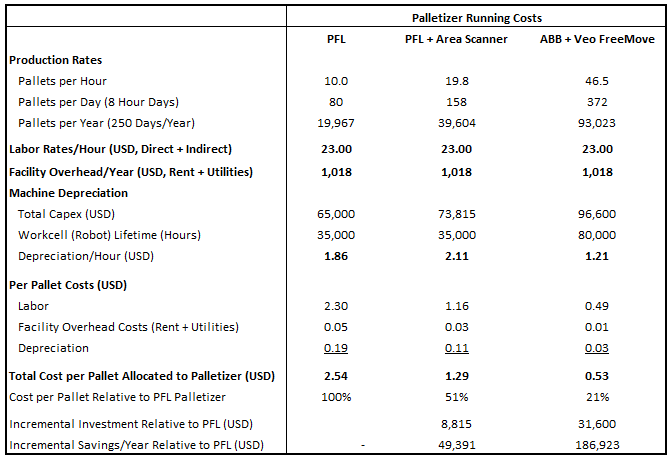

To make a solid economic comparison between the different palletizer configurations, we need a model of the costs per pallet. There are, broadly, three types of costs that must be allocated to each pallet: labor costs, space utilization, and machine usage.

All three palletizers require humans to replace full pallets with empty ones, in a continuous cycle. We assume that all three palletizers require one FTE to tend to the workcells, at a fully loaded labor cost of USD 23 per hour. Obviously, the more pallets per hour that can be assembled, the lower per-pallet cost.

Space utilization captures all fixed overheads in the factory, such as rent and utilities. We assume total imputed rent is USD 6.36/square foot and the workcell is 4x4m, or USD 1,018/year. Again, the more pallets per year we can assemble, the lower per-pallet cost.

The capital expenditures and commissioning costs are amortized to a per-hour basis based on the robot lifetimes. The ABB + Veo FreeMove palletizer is the winner here as it has double the lifetime of the PFL robot. These per-pallet depreciation costs are lowered further when we include the higher pallet throughput of the ABB + Veo FreeMove palletizer.

Figure 6 summarizes the economic models for the three palletizers. In summary, we estimate the per-pallet costs of the ABB + FreeMove palletizer to be about 80% lower than that of the simple PFL workcell, and less than half that of the PFL robot guarded with a 2D scanner. Capital expenditures and commissioning costs are indeed higher, but given the higher pallet throughput, those costs can be paid back in just a couple of months of operation. A no-brainer indeed.

One could argue that perhaps we should fit the ABB IRB2600 robot with the 2D scanner and reap even more cost savings. In principle, this sounds reasonable. However, the lack of dynamic 3D imaging and no simple automatic restart after 2D scanner trigger works against this option.

Further, the flexibility of FreeMove (relative to the 2D scanner approach) allows for more cost-effective process re-configuration, should the profile (size, weight, amount) of the items to be palletized change. As we’ve seen in previous blog posts, there is value in flexibility, and the value of quick reconfiguration in palletizing is no different.

Obviously, if you are running a slow production line with lightweight cases and small pallets, and the throughput of the PFL palletizer is sufficient for your purposes, that is the best economic option: the PFL robot is easy to install and program, user-friendly, has many safety features, and is the least expensive overall. However, if the palletizer step is a bottleneck, and you need speed and flexibility, Veo FreeMove, coupled with a traditional industrial robot, is an excellent alternative.

Figure 6. Economic model for the three palletizer configurations.

[1] This is not surprising. Quality PFL robots have many on-robot safety features that mechanically hinder the allowable speeds. Additionally, they are usually fitted with lower-torque smaller motors, resulting in a lightweight footprint. For example, the Universal Robots UR 10e weighs a modest 34kg. By comparison, a traditional industrial robot such as the ABB IRB 2600 is built like a tank. The downside is that it weighs close to 300kg and requires 200-600V to operate. Even the robot controller is built for abuse – the ABB IRC5 controller weighs 150kg.

[2] Even though it is built like a tank, it does not have many on-robot safety functions. It is also a standard high-volume robot from ABB, which benefits from production economies of scale, as ABB makes dozens of robot models, many with common and interchangeable parts.