Veo FreeMove® is an advanced safety system for industrial workcells with human-robot collaboration. The system monitors workcells in 3D and implements dynamic Speed and Separation Monitoring as defined by ISO 10218-2:2011 and ISO/TS 15066:2016, enabling safe interaction between humans and robots.

Veo FreeMove® is available to ship with ISO 13849 certification for PLd, Category 3.

System Components

Powerful software running on fail-safe hardware

FreeMove Sensors®

Wide field of view, long range 3D Time-of-Flight sensors (up to 8) with dual imagers enabling per-pixel validation.

FreeMove Engine®

High-performance industrial computer with dual motherboards checked by a safety processor, which processes sensor data and interfaces with the robot and other hazards.

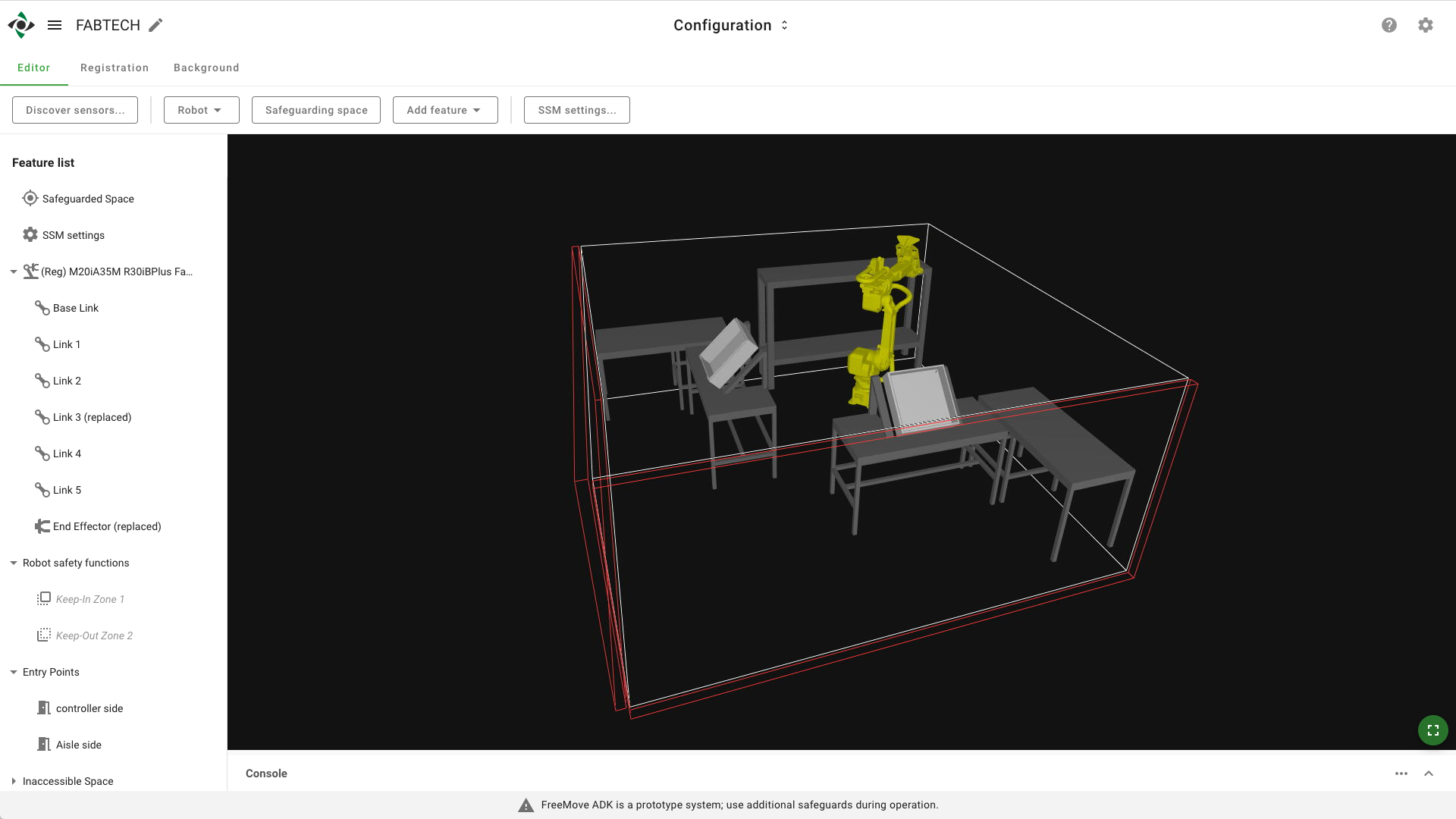

FreeMove Studio®

A browser-based application which runs on a standard PC for configuration of FreeMove ®.

FreeMove® Advantages

Functional Safety: PLd, Category 3 per ISO 13849-1:2015; Approbations: UL 508:2018, CSA C22.2

Safety Certified

3D Safeguarding

Monitors the entire volume of a workcell in 3D, ensuring that the robot operates safely in any scenario, and implements dynamic Speed and Separation Monitoring (SSM) as defined by ISO 10218-2:2011 and ISO/TS 15066:2016, enabling safe interaction between humans and robots.

Dynamic Protective Separation Distance

A real-time understanding of the space enables dynamic computation of the extent of this robot hazard, which moves with the robot and workpiece. It calculates possible future robot positions and signals the robot to stop by sending safety outputs that indicate if the robot is closer to a human than the Protective Separation Distance (PSD).

Connection to Robot Controller

Responds to a PSD violation by issuing a dual channel safety output signal to indicate whether or not the robot should stop. When the PSD violation is cleared, FreeMove® allows the robot to safely restart.

Static Hazards

Safeguard additional non-robot hazards such as conveyors, workpieces, fixtures, etc.

Tracked Objects & Dynamic Blanking

Blank large objects in your workcell such as workpieces so they do not trigger PSD violations.

PLC Support

Supports common PLC architectures such as Allen Bradley and Siemens.

Specifications

Robots Supported

FreeMove® supports most common articulated industrial robot configurations:

- Up to 6 active, revolute joints

- Open chain kinematics and parallel 4-bar kinematics

- One passive prismatic joint, such as a balancer spring

Robot Controllers Supported

ABB: IRC5

FANUC: R30iB, R30iB+

KUKA: KRC4

Yaskawa: DX200, YRC1000

Example Applications

Suitable for collaborative applications such as:

Machine tending

Collaborative palletizing

Operator load station

Human access for visual inspection or fault recovery

Parts presentation for assembly or quality

Detection Method

FreeMove Sensors® use active infrared (IR), Time-of-Flight technology (850 nm)

System Specifications

Power Consumption: ~ 1,600 W for an 8 sensor system

Power Requirements: Single phase, 200-240 VAC, 50-60 Hz, 20A mains power

Engine Dimensions: 584.2 mm (23.0 in) wide, 646.2 mm (25.4 in) deep, and 1088.7 mm (42.9 in) tall

Engine Weight: 128 kg (282 lbs)

Sensor Dimensions: 190 mm (7.48 in) wide, 120 mm (4.72 in) tall, and 82 mm (3.23 in) deep

Sensor Weight: 1.63 kg (3.59 lbs)

Operating Temperature: 0° C to +45° C (32° F to 113° F)

Humidity: 0 to 95% relative humidity, non-condensing

Enclosure Protection: IP54 (Engine), IP65 (Sensors)

Up to 8 sensors supported by a singular engine depending on workcell geometry

Explore Industry Knowledge & Applications

Benefits of FreeMove®

Reduces the cost and complexity of designing and integrating workcells with human-robot collaboration.

Improves productivity by reducing downtime while improving human and robot utilization.

Improves safety by monitoring the entire workcell in 3D, ensuring that the robot operates safely in any scenario.